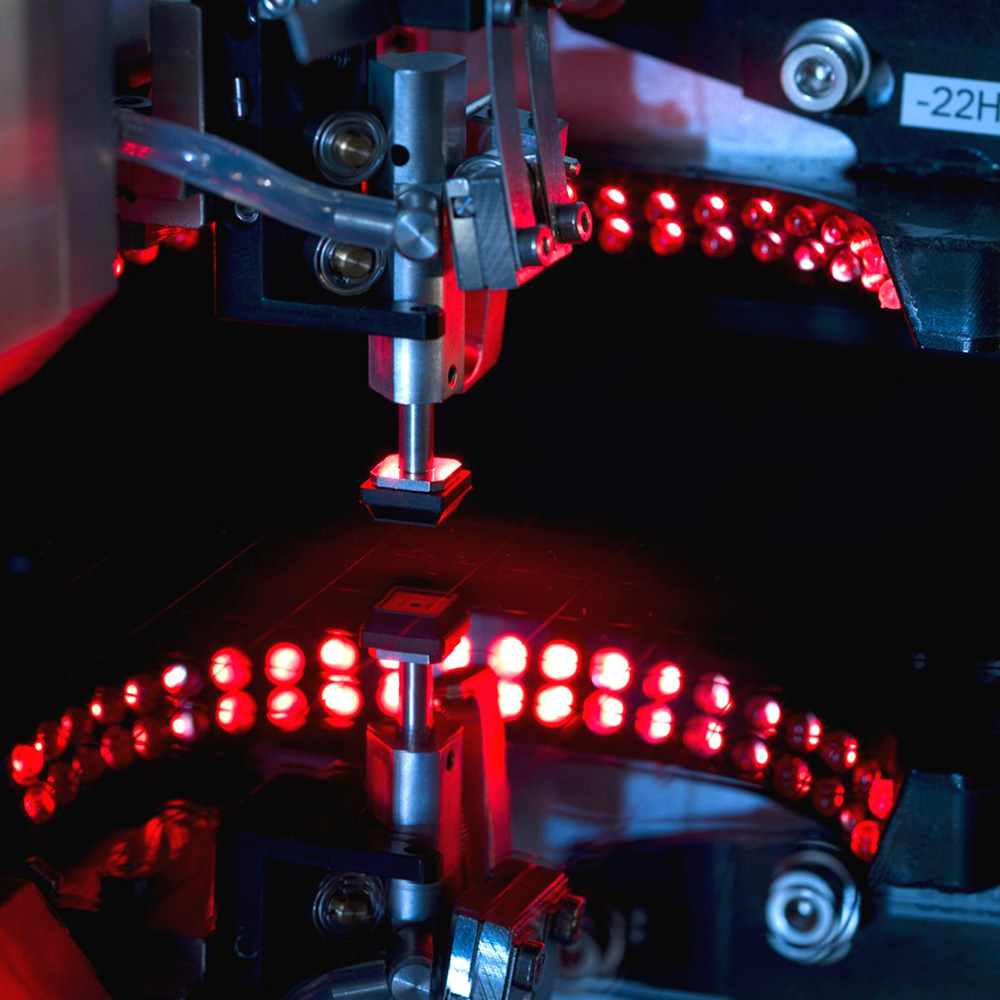

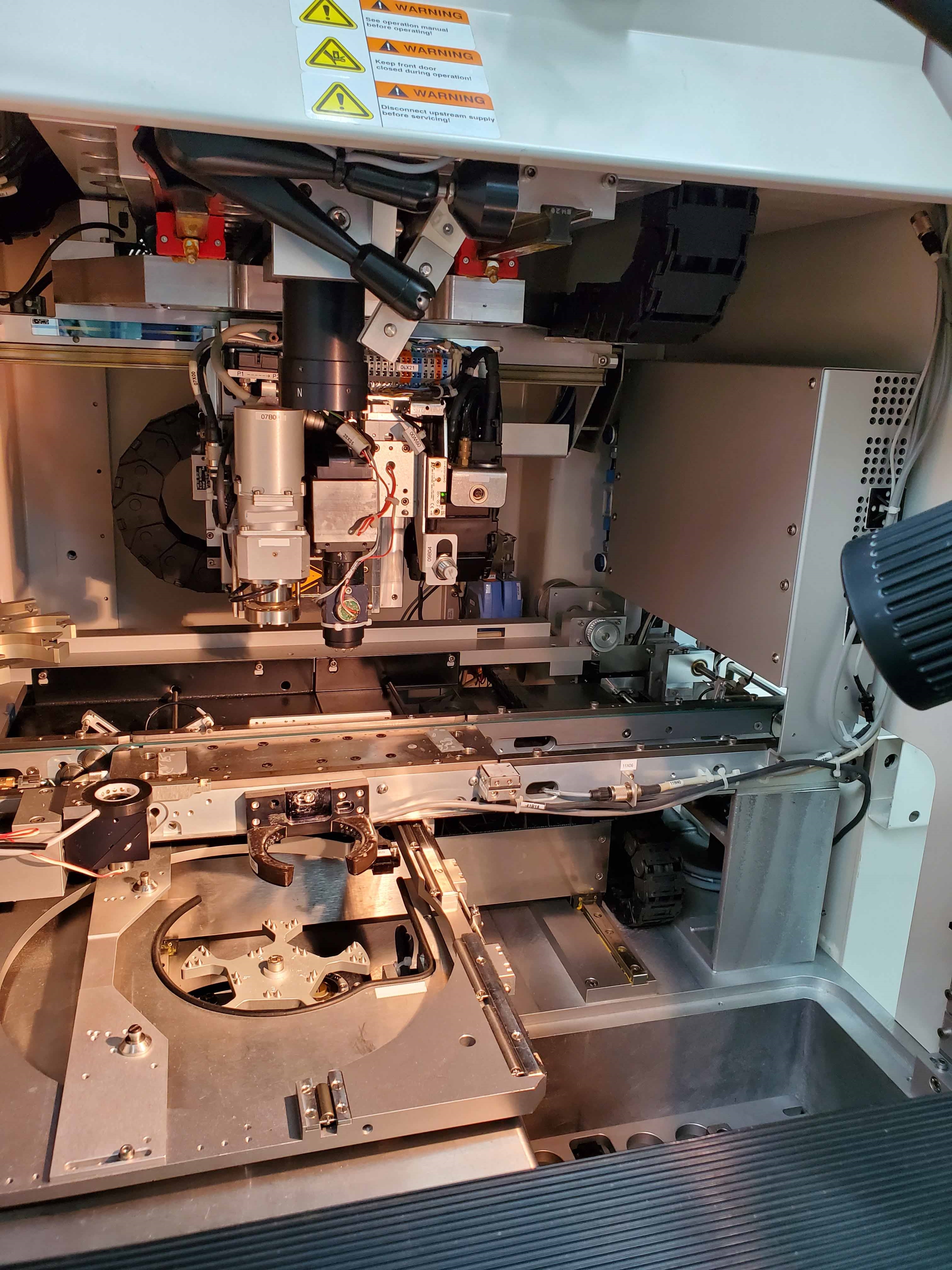

Reliable and accurate flip chip processĭATACON 8800 FC QUANTUM SIGMA The Datacon 8800 FC QUANTUM sigma flip chip bonder represents the next generation of the high-volume, high-accuracy 8800 platform.Operator independent results ensured by auto calibration.Full recipe transfer from machine to machine.Load recipe from host and run on any machine.Innovative parallel activity machine design with Phi-Y movement pick-and-place.Low vibrations – no time wasted for motion settling.Simultaneous movement of chip and camera – no time wasted for image taking.Equipped with integrated dispenser, 12” wafer handling, automatic tool changer, and application specific tooling, the 2200 evo is prepared for present and future processes and products.ĮSEC 2100 FC PLUS Esec as a renowned leader in providing die bonders for trouble free high quality mass production has integrated flip chip capability into its 2100 family of die bonders: Esec’s response to driving down the cost of flip chip technology. Test Handlers, Test interfaces, ManipulatorsĭATACON 2200 evo The 2200 evo high-accuracy multi-chip die bonder provides the ultimate flexibility for die attach as well as for flip chip applications.

For more information, visit Frontier Coater Combined with additional web-based tools for vacuum sputter deposition, reactive ion etching, wet chemistry, and interlayer alignment, providing access to an emerging set of tools not found anywhere else. Located on the 4th floor in the Life Science Laboratories the Roll-to-Roll Fabrication facility provides a unique set of custom, moving web-based tools for the translation of advanced materials and nanomanufacturing processes to industrially relevant scalable platforms for the development of next generation life science innovations in biosensors, diagnostics, and platforms for personalized health monitoring.

0 kommentar(er)

0 kommentar(er)